- Por, Vadodara, Gujarat

- GST NO. : 24AABCM2845B1Z0

- +91-9998967136

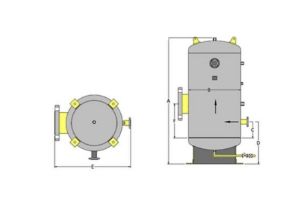

Basket Strainers

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Basket Strainers |

| Material | Metal |

| Shape | Round |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Principle Of Operation

Air Eliminator consists of top nozzle housing with float assembly which is made up of float and guide rod. Now when product is entered into air eliminator which consists of air / vapor through inlet nozzle it enters into large open vessel area which decrease the velocity of the fluid and try to bring liquid to the stable state and as flow strike to the baffle plate which separates liquid and air / vapor which again travel to the top of the vessel and release through the float assembly. Now when air is released and further liquid level is rise up to float assembly will push this assembly up and close the orifice area.

Now when more air is coming into the system or vapor is generated it will again travel to the top and accumulate in the top housing and at a certain stage when collected air /vapor forces liquid level down, buoyant force acting on the float reduces, this will reduce float buoyancy and float drops down which allows air / vapor to escape through the seat orifice. Now as fluid replaces air, Float buoyancy again increases and allowing float to rise and close to orifice seat.

We also offers Split type Air Eliminators for fuels like Aviation Turbine Fuel.

We offer Air Eliminators from 25 ltrs to 6000 ltrs with size of 1” to 24” with 150# to 600# with design as per ASME Section VIII div I.

We have credit of supplying a more than 3000 units by 2018.

Benefits

- Air Eliminators are bidirectional. It can be installed for flow direction Left to Right as well Right to Left.

- Vertical design which reduces installation space.

- High capacity air elimination provides good accuracy with safety of metering device

- Simple interface with PD Meter, Mass Flow Meter, Turbine Meter

- If Used with Thermal Relief Valve protects all system components.

- Accurate Measurement.

- No complicated design for maintenance.

- Zero drain facility.

- Stainless Steel internals.

- Higher air eliminator retention time can be customized.